Women Are Poorly Served By Designers

You'd be surprised how many products and systems are designed for men and then translated, often badly, for women

Women are 47% more likely to be severely injured in a car crash, but female test dummies could change this.

Crash test dummies have been used to test car safety since the 1970s, but most of them are modelled on the average man. It is only in the past three years that a crash test dummy, specifically designed around female anatomy, has been available to study the effects of car crashes on women's bodies. Prior to this, the stand-in for women in these tests was a scaled-down male model, which was actually the size of a 12-year-old, girl.

The work done by Dr Astrid Linder has shown that women suffer more and in different ways to men, because their torso rigidity, joint stiffness and organ positions are, obviously, different. The same problem exists in medical device and drug development: to avoid the expense or perceived "complexity" of mixed clinical trials, these are usually conducted exclusively on men and the results extrapolated for women.

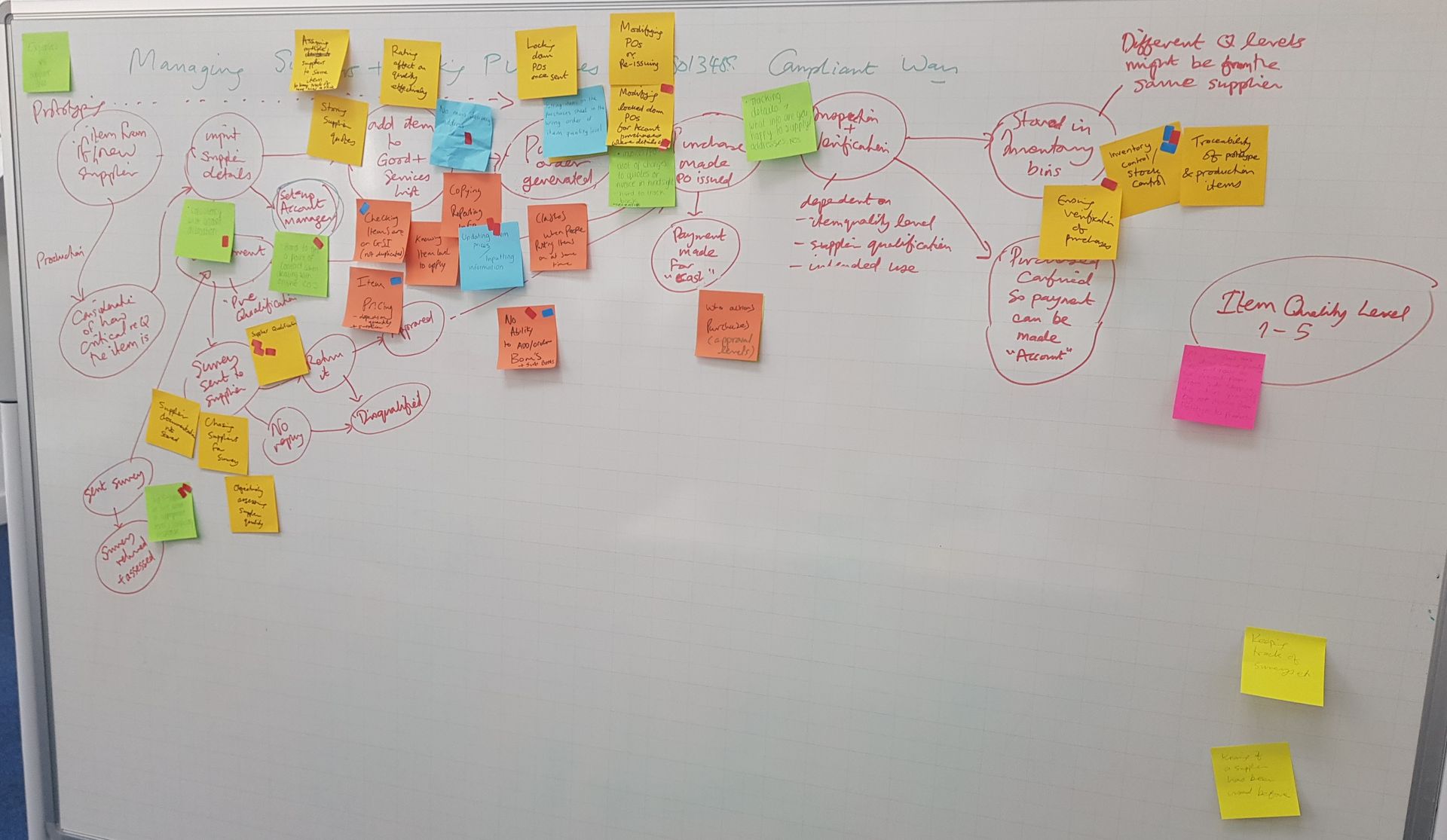

This is completely opposite to our vision of user-centred innovation! There is a lot we can and should do as designers to remedy this problem - we would never design for people without them directly being involved. This applies to products and services for women, and those that are used by people with physical and hidden disabilities, and by the elderly.

We have designed public seating for older people, hygiene products for people of the Muslim faith, devices for interventional cardiology and a sea safety system for sailors. None of our team had direct experience of the use cases, so we had to engage with stakeholders and users very early on so we could co-create the requirements and how we could test aspects of the solution as it developed. Often, data was not available, nor accurate anatomical models for the actual people we were designing for, so we have to research and create the data to inform our design process. It's central to our approach and, we believe, essential to ensure the commercial success of any innovation.

Jonathan recently designed a product for Zephyr Ease to help women recover after giving birth through C-Section - a situation which he had no direct experience of. So, how did he go about developing a solution? He'll write a blog about it next month!