Rapid prototyping saves ancient Chinese instruments

3D Printed parts save ancient instruments for the oldest Chinese youth orchestra in Europe

We have worked with the Liverpool's Pagoda Chinese Youth Orchestra (PCYO) before. In 2023 we designed and built a complete drum kit using a substantial proportion of bamboo for the Imagine Bamboo is Everywhere community arts project. As part of the delivery team, we won a Liverpool City Region environmental award.

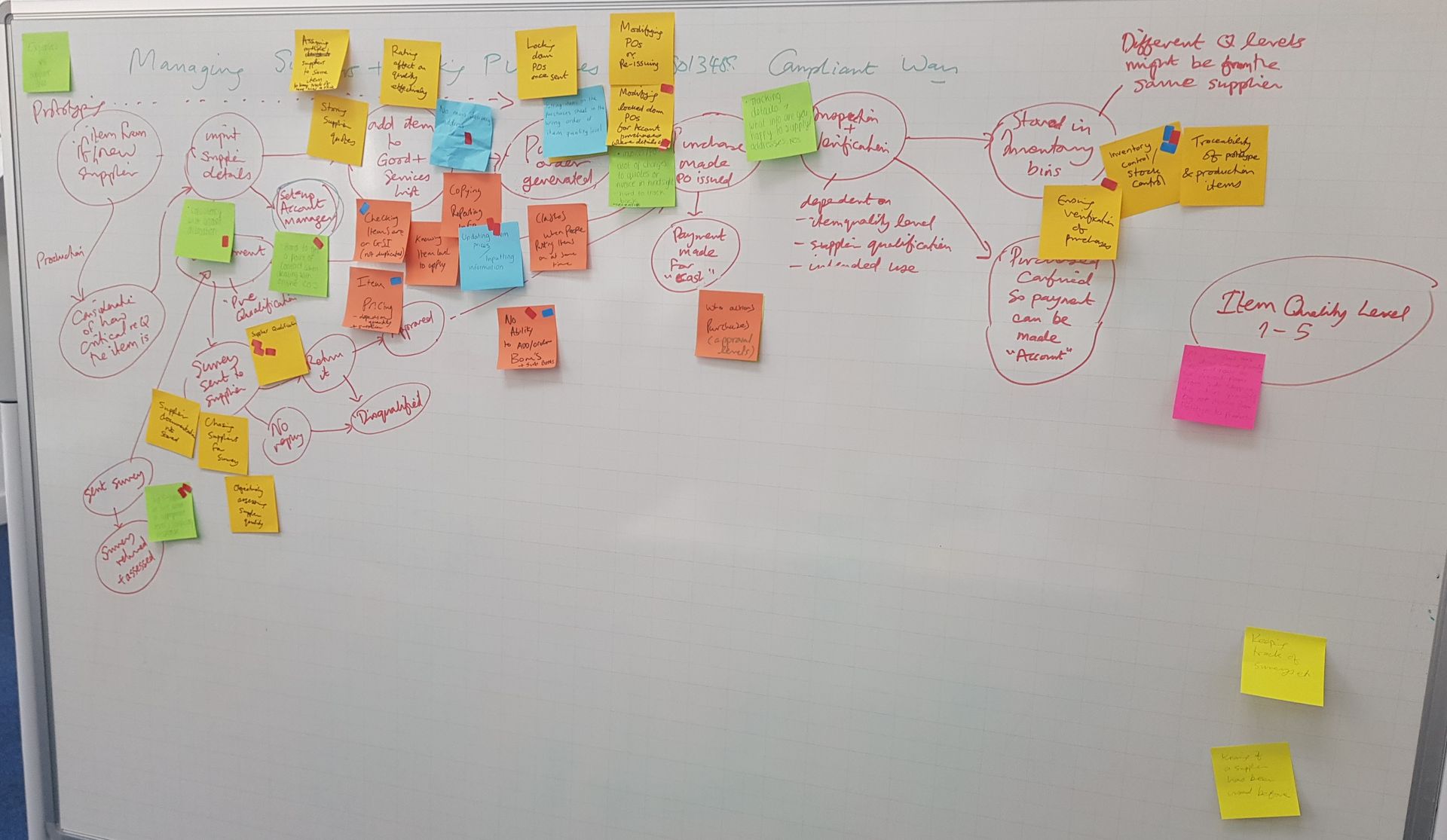

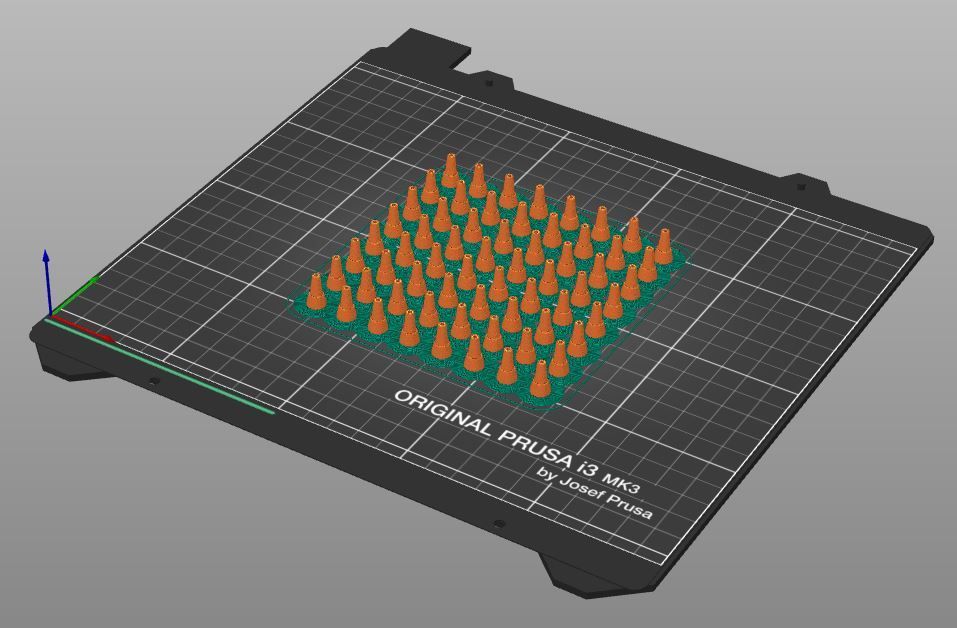

Recently we were shown a number of traditional Chinese instruments that needed spare parts that are, no longer, available. Several four-stringed Pipas, sometimes called a Chinese Lute, needed pegs to secure the strings to the base of the instrument. After some trials we developed the parts in 3D CAD and then built them in ABS plastic on our desktop 3D printer. It was important to ensure that the shapes and materials had equivalent acoustic properties to the originals, and that they were stable with time under load. Also, we had to allow for shrinkage of the polymer during cooling so they would fit snugly in the holes of the Pipa.

This demonstrates that a basic knowledge of 3D CAD and a low-end 3D printer can extend the life of physical objects even if spare parts are no longer available.

Zilan Liao, CEO of Pagoda Arts, said "the parts work well". We are now supplying string bridges for another instrument, a hammer dulcimer, called a Yangqin.