What is an Innovation Ecosystem?

You have to be on the ground to see the wood from the trees!

Innovation Ecosystem is popular term at the moment. In my region, there have been mapping exercises to identify the key players, but they usually end up only identifying Universities, Science Parks, Large Research Organisations, Car Manufacturers and A Niche Luxury Product Producer.

It is usual for larger institutions to dominate the discussions about Innovation Ecosystems, become the gatekeepers for funding and then put on events, solely for the purpose of driving SMEs to themselves. This is despite the evidence that they are only part of the story.

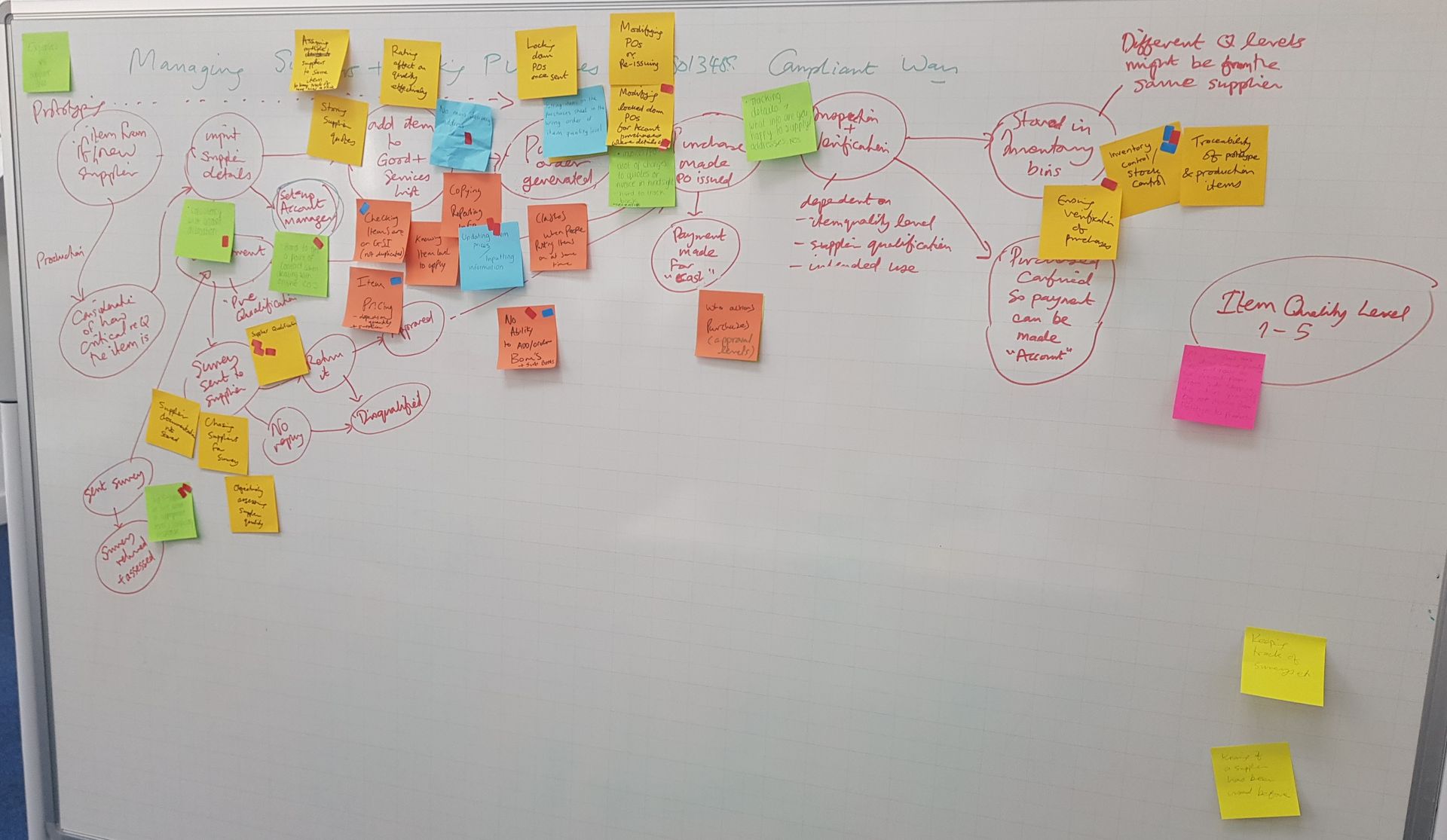

In contrast, one recent class IIb invasive medical device project we delivered had this DNA…....

University IP > Grant Funding > Private Sector Partner > Research Organisation > Design > Prototyping > IP Protection > Supply Chain > Tooling > Batch Production > Regulatory Compliance > Product Technical File > Instructions For Use > Verification in Lab > Commercialisation…..

We managed much of the project and did quite a bit of the work ourselves, commissioning other experts when necessary. This is quite typical of how we and other Industrial Design Consultancies can integrate with other knowledge specialists and sub-contractors.

We have a good track record of winning Innovate UK, NIHR and Private Equity Funding for our clients. Despite this, we are very small and agile but have a big impact.

We have a focus on commercial outcomes. The following always makes me chuckle -

- Research turns money into ideas

- Innovation turns ideas into money

Too many of the large Innovation Ecosystem organisations are more suitable for and more experienced in point 1, so it's questionable that they should be the self-appointed gate-keepers.