Shortlisted for the LCR Culture and Creativity Awards 2025

An innovative way to reduce landfill and get a good night's sleep

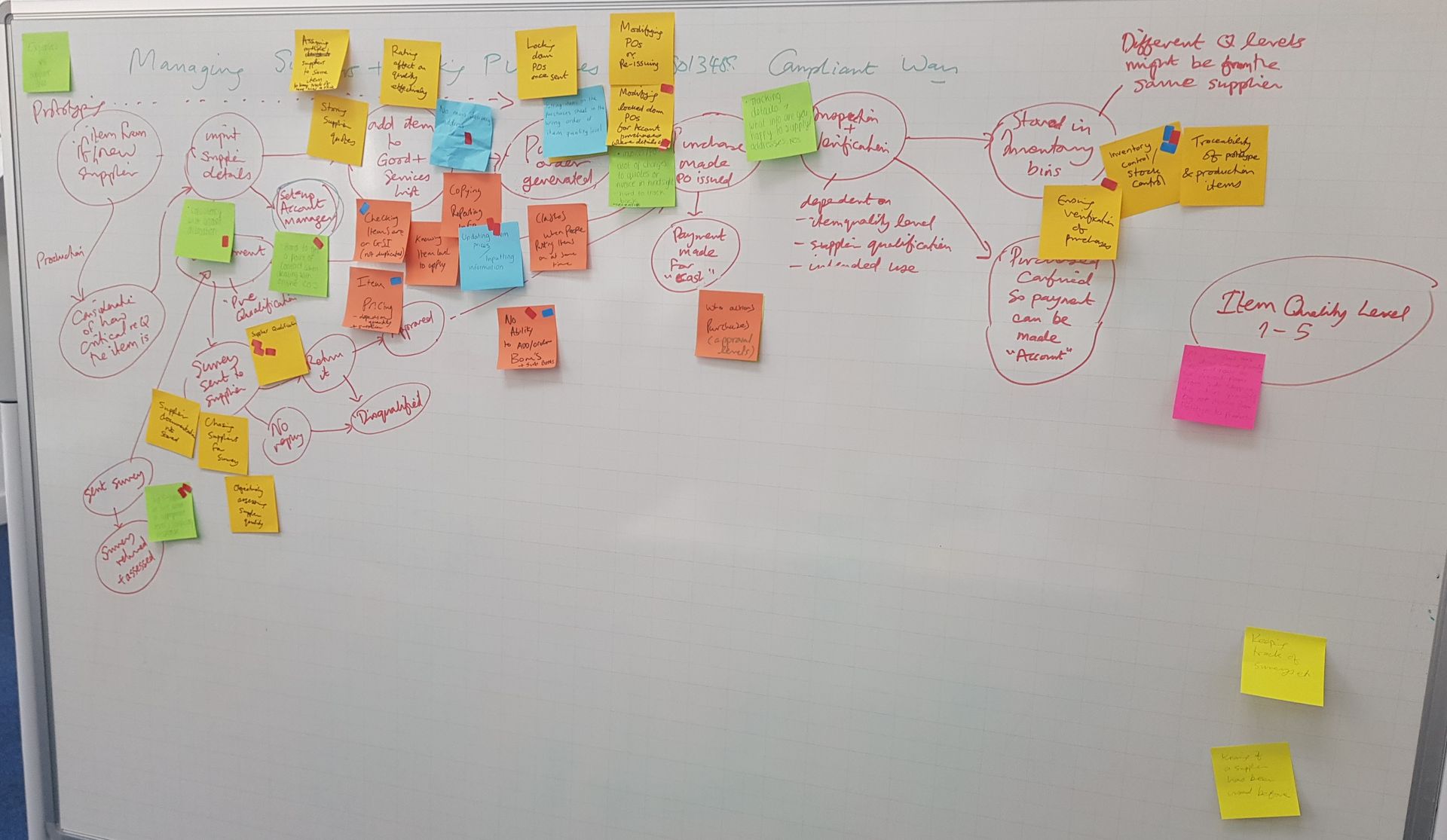

Butters Innovation is delighted to announce that we are finalists in the Innovation category for the Liverpool City Region Culture and Creativity Awards. We worked with local charity FRC Group to develop an automated machine that processes mattresses. Developing their own products and machines was new to FRC Group so they commissioned us to deliver the solution.

The machine (first of its type in the world) has been named Mattilda and enables large volumes of mattresses to be given a new and extended life, safe for use. The cleaned mattresses go to alleviate furniture poverty and are used to maintain cleanliness in student residences, social housing and hotels.

The seven stage process ensures pre-owned mattresses, which may have been destined for landfill or broken down into parts for recycling, can be processed to remove:

- Odours

- Stains

- Bacteria

- Viruses

- Mould

- Mildew

- Bed bugs and fleas

The mattresses are restored to extremely high cleanliness levels and are as good as new. They are swabbed to certify that they are clean to the necessary standard. This is great news for the environment too. Every mattress which is reused saves 79.5 kg of CO2 which is the equivalent of taking 14 cars off the road for a day.

Following the first stage of the work supported by a grant from Made Smarter, we completed the final stage of the work this year with funding from Innovate UK (Launchpad - Advanced Manufacturing - MFA - Liverpool City Region) to design and implement additional drying, flame retardancy spray restoration and cloud-based monitoring. Jonathan Butters, CEO of Butters Innovation, helped FRC Group apply for the funding.

CEO of FRC Group, Shaun Doran, commented:

“We are delighted to introduce our UltraClean Machine. This is the first of its kind and will make such a huge difference in our mission to End Furniture Poverty. Those in need will receive high quality mattresses, and at the same time this will have a positive impact on the environment, as disposal or recycling is not needed. “

The first prototype of the machine won the prestigious MRW National Recycling Awards, the top awards in the recycling and resource management sector.