What’s “design thinking” got to do with my business?

Charlotte Corke explains that it could be just what you need to unlock innovation and creative problem solving in your organisation.

Are you grappling with inefficiencies and frustrations in your “business as usual” way of doing things?

Wanting to branch out into new markets, or develop a new product or service, but struggling to work out where to start?

Is customer engagement or retention an issue but you’re not sure of how to tackle this?

In all these examples, and many more, Design Thinking could be just what you need to unleash the creative problem solving of your team and radically

improve your business. It’s a human-centred process, which uses tried and tested tools and techniques, to help you reframe problems, overcome biases and unblock the imagination and innovation of your in-house teams.

And although there's a fair bit of hype around about Design Thinking, it’s really not that complicated. In essence, it’s about:

- Ensuring that, when you are working to solve a problem, you first make sure you really understand that problem from all angles, taking into account the views of everyone affected (recognising that their views may be very different from your own)

- Not trying to solve it in isolation - good ideas don’t come from divine intervention but are a product of past experiences and knowledge of other solutions, to similar or contrasting problems

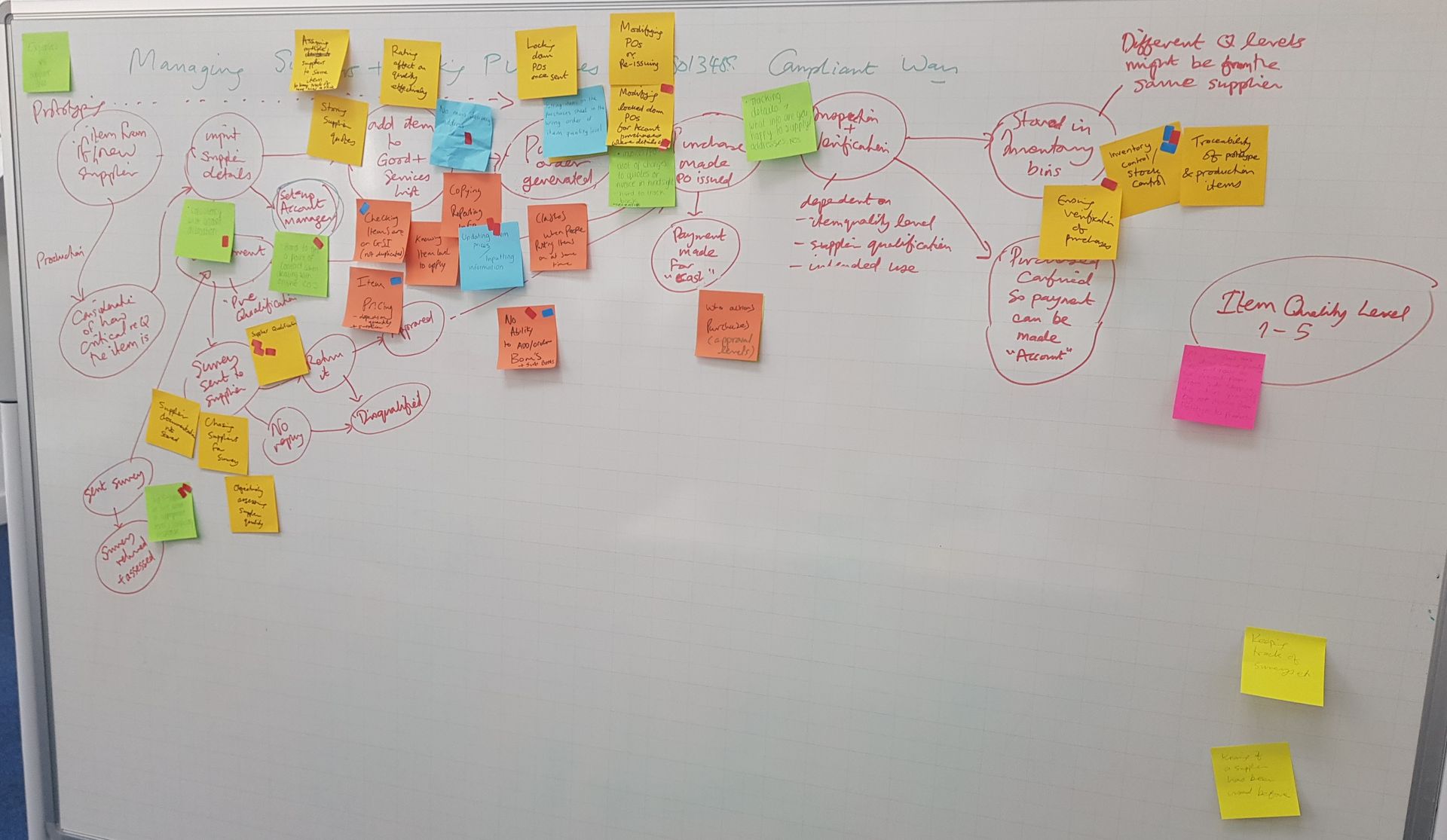

- Not settling for the first solution that pops to mind but rather, exploring a range of options, digging into them in increasing depth, by collaborative discussion - then prototyping and testing (physical, digital, organisational, or whatever applies to your problem space) with real users or customers - to learn and develop, iteratively moving towards a solution.

Sounds messy, right? Well yes, it can be - but it’s also proven to be great at getting to solutions which are

unexpected, delightful, engaging and effective.

I’ve helped many different types of business tackle their

knotty problems in this way:

- a large, multisite utilities company that needed to improve internal communications and ensure its people were informed and enabled to do a great job

- a digital startup that was developing a platform for supply chain management, that needed to unpick its user journeys and make sure their platform enabled users to complete key tasks in an engaging way

- a medical device company looking to develop a new product to address a clear problem with multiple possible solutions

- another digital startup that was grappling with its value proposition in a complex business-to-business ecosystem that needed to figure where to start in its development journey.

None of these sound particularly like “design” related projects and yet, Design Thinking was at the heart of devising a credible plan that addressed the full trinity of business success - Desirability, Feasibility and Viability. By allowing their teams to engage in this process, these organisations unlocked their insight, talent and motivation to define and design the changes and developments that were needed.

Are you grappling with a knotty problem? Let’s have an initial chat to see if it’s something we can help you with!

Charlotte Corke

Principal Innovation and Start-up Consultant